Where’s Vulcan?

The following article was recently published by James Blatch in his email newsletter. James is author of the novel, The Final Flight. His father, John

Our thanks to Jeremy Lewarn who recalls his time in the RAF in this detailed article.

My memories of the Vulcan start from when I first joined the RAF in 1971. I’m still not sure how, but a very good recruiting sergeant managed to persuade me to take a 2 year apprenticeship as a Craft Apprentice (Weapons), common name Armourer or colloquially a Plumber. Well it sounded good at the time. Why Plumber for an armourer you may ask. It came from the fact that armourers were responsible for the gun turrets on the older aircraft (Lancaster, Wellington etc.). These turrets were hydraulically operated and that means a load of pipe work, and pipes means plumbers or at least it does as far as the story goes. Plumber has stuck and is still in use now.

So during my 2 years at RAF Halton (where all the aircraft apprentices went at the time) and as part of 222 Craft Apprentice Entry, being taught the many and varied parts of the aircraft and weapons that I would be dealing with when out in the real Air Force, I first came across the Vulcan. We were taught the 1,000lb bombs in all its various guises and how it was fitted to the Vulcan. We were taught the 7-store carrier and all its components. We were even given an insight into the bombing system although this was mostly looked after by the Armament Electrical Trade. We were also taught all about the Vulcan ejection seat, the Martin Baker Mk 3KS as I remember. When it eventually came time for us to put some of this knowledge into practice during what was called the airfield phase of our training what better aircraft could there be for trying out our 1,000lb bomb preparation and loading skills, but the Vulcan.

Some years previously (in the 60s) a very brave, some might say foolhardy, crew had brought a very light Vulcan into land on the grass runway at Halton. They had waited until summer and for a dry spell of weather before attempting the landing but it was an aircraft well worth the trouble from my point of view. I understand that there were 3 Vulcans landed at Halton so they must have been desperate to use them for training at the time. Vulcans XA898 landed on 26.8.64, XH479 on 28.6.67 and XA892 was flown in on 21.6.62.

The practice load went something like this. Having prepared our practice 1,000lb bombs with fuzes or pistols and tails as appropriate to the mission, we then had to load them on to the bomb trolley (Standard Airfield Bomb Trolley or SABT). There are nice cut-outs in the trolley to accept the 7 bombs, and the 7-store carrier can then be lowered into place atop the bombs and hopefully all bombs crutched onto the carrier. We also used a S Type trolley as well on occasions which was lighter and slightly easier to steer.

Off we go to the aircraft, the bombs being towed to the aircraft and manoeuvred close to the bomb bay. Four guys (there weren’t any girl armourers until much later in my career) then had to inch the trolley into position using a hand wound gear mechanism on each wheel and one poor lad trying to lift the large tow bar and steer the monstrosity into the correct position. The wheels of the trolley were independently steerable using the inching gear but it was still a major exercise if the tractor driver didn’t get it right. Now hopefully in place under the correct station in the bomb bay the motor powered hydraulic power pack was brought in. Two large hydraulic jacks are taken off the power pack and manhandled (2 men lifted or 1 man lift and drag) under the 7-store carrier at each side. If needed the C-Type hoist was attached to the front of the trolley and the nose of the centre bomb. This particular bit of kit is so that the bombs go up level as they could be tail heavy if certain types of tails are fitted.

OK, motor started on the power pack, usually after much swearing and playing about and the power pack operator can now start to extend the jacks up through a hole in the 7-store and up towards the suspension point (HASU) in the bomb bay. Leave the jack head just short of the HASU and get the jack handler and the power pack operator to lift the jack, tilting it slightly so that it hooks into place on the HASU. The power pack operator then runs around the load and helps the other jack handler to locate his jack correctly. Now the good bit, unlock the bombs from the trolley and with the winch operator letting out his winch cable, raise the load to the bomb bay, keeping it as straight and level as possible. Having pulled the bombs and carrier tight to the crutching points the jack handlers now have to get very long winding handles (part of the power pack kit) and place it in a socket on the carrier and wind away to lock the carrier on to the HASU.

Making sure that the number of turns on each side is the same (showing the carrier is level), the power pack operator lowers the jacks slightly and hopefully the bombs and carrier remain in place. Now extend the jacks and remove them and replace on the power pack. Meanwhile a large ladder is placed next to the carrier so that the team leader can climb up to the carrier and do the electrical checks and connections. Even though they were practice weapons and there were only 7 and not the full load of 21, that bomb bay is an impressive sight and we were all impressed and couldn’t wait to try out some real loading, out in the RAF proper.

Near the end of my training we applied for postings around the UK. I had applied for St Mawgan, Mount Batten or Chivenor as they were the closest to my family home in Plymouth. Unfortunately during the period between me applying for these units and when I would know where I was posted, my mother died and my brother was planning to emigrate, leaving me with no close relatives in the area. When I was offered Chivenor I therefore decided that I would swap postings with a lad who was really keen to get to that area of the country. The lad in question had been posted to RAF Scampton on the Vulcans.

So having passed out from Halton as a Junior Technician I arrived at Scampton and started what would be a 5 year tour there. The main role of the Scampton Vulcans at that time was the nuclear deterrent (not the primary deterrent as this had passed to the Polaris) and having fairly recently got rid of the Blue Steel Missile role they were now equipped with WE177 (950lb) free fall nuclear weapons. There were also maritime reconnaissance aircraft on 27 squadron but these were not used for loading all that much. I believe I would have seen XH558 at some time during my days at Scampton as it was one of the MRR aircraft, I may be sad in some respects but I can’t remember tail numbers that far back.

The armourers at Scampton were not attached to a squadron. The first line armourers were centralised and went out to whatever aircraft needed work. The armourers also had some second line servicing facilities for the carriers, dischargers, the explosives and ejection seats as well as the nuclear site. The Scampton Vulcans did not have a fully defined conventional bombing role at that time but all the armourers had to keep their hand in by going over to Waddington every so often to re-certify on the preparation side. The loading could be done at Scampton with a practice load and was very similar in many ways to the nuclear load.

I worked in most of the armament sections and was part of a nuclear load crew as jack handler and latterly as the power pack operator. Some great memories of the time there some of which I will share and some I don’t think I can in mixed company.

I do remember that we had to re-certify the weapon loading at very regular intervals; well you wouldn’t want people forgetting what to do with the ‘bucket of sunshine’ would you? As part of the regulations for handling nuclear weapons there have to be 2 people to do any one job (the 2 man principle) the logic being that hopefully this would prevent one person going mad and blowing everyone up! Well it gets boring after a while wandering around with 2 people doing one job, so to brighten the day up you could sometimes see a couple of burly armourers holding hands and skipping around the aircraft. Not a sight for the faint hearted and most upsetting for the policeman on guard who was probably trying to take it seriously. This was obviously frowned upon by the powers that be, but even the load team leader wasn’t always squeaky clean. I remember one exercise where we had been called in by the siren at stupid o’clock in the morning and were for some reason short handed, rumour had it that some armourers were still under the influence, I don’t believe it myself because we were such clean living lads. There was a requirement for us to generate (load and prep) a certain number of aircraft within a set time period from when the hooter went. Well we had loaded a couple of aircraft already that morning and were straight on to the third and our Chief, who was of the old and bold variety decided that during the electrical tests and connections he couldn’t be bothered to climb down the ladder from the bomb bay, have us move the ladder to the other side and climb up and down again. So instead he just shoved the test kit across the top of the carrier and with one foot on the bomb shuffled across to the other side and started the test while we moved the ladder so he could eventually get down. He was supposed to have someone observing him at all times but these were practice weapons and we were in a rush but we did have to wipe his size 10 footprint off the bomb in case the guys in the bomb dump tried a little gentle blackmail when they got the weapon back.

I talked about the first time I loaded the Vulcan during training and that is the proper way to load the aircraft using 2 men per jack, a power pack operator and a load team leader. This was the same for smaller practice weapons fitted to a carrier and then fitted to the 7 store as well as the “bucket of sunshine” or the 1000lb iron bombs. However, when push came to shove a load crew could consist of 2 people. I only did this once as it was not recommended and we would have been in the clag had we been caught. It was during the few days between Christmas and New Year and no one wanted to be there but for some reason the aircrew wanted to go practice bombing so we had to load a couple of aircraft with carriers and 28lb practice bombs. There were only a couple of us in the Armoury when we got the call that the aircraft was ready for the load and where were we? I was an experienced power pack operator by this time and the Chief said come on we’ll get everything ready and the others can join in when they get back from the other job they were on. No problem! We hooked up the power pack to the land rover and drove to the aircraft where the dumpies (lads from the Bomb Dump or Explosive Storage Area) had delivered the Practice Bombs on the carriers. While the Chief checked switches and other bits and bobs I lugged the Jacks off the pack and set the rest of the kit out. The Chief came back and between us we managed to manoeuvre the trolley with the carrier on under the bomb bay. Well we’d got this far on our own so with no sign of the rest of the crew the Chief says I’ll handle the jacks you just operate the pack. OK, I raised both the jacks through the hole in the carrier got the Chief to tilt one a little and got it so that he didn’t have to lift it at all to hook it on to the HASU. Same for the other side. I had to be a little careful getting the jack that high as it was really close to the skin of the bomb bay and a hole in the bay would not be appreciated. This was why the jack head was supposed to be a lot lower than the HASU and then lifted in. Undoing the locks on the trolley I raised the load and it locked in perfectly. With the jack operating levers pushed over centre they kept the pressure on while I wound one side in and the Chief wound the other side. Similar manoeuvre to get the jacks down and stowed. Electrical checks were carried out same a usual. At this time the rest of the team arrived just in time to sign up! Not the recommended method and hard work, but safe when we new what we were doing.

Another abiding memory is being perched on top of the Vulcan with the canopy removed directing a crane over the top of me so as to remove the ejection seats. It’s a long way up on the back of a Vulcan with no visible means of support or it certainly felt that way to yours truly.

Although that was pretty hairy it was even worse when there was no crane available and the seat had to be manhandled out. This was achieved by 2 armourers with the canopy removed, the seat mostly disarmed and one on top of the aircraft pulling and operating the top lock and one in front of the seat lifting in the most awkward position imaginable. As the seat was slid up the guide rails we would guide it as gently as possible on to the aircraft skin, the guy inside would get out of the cockpit and with much grunting and groaning the seat was lifted towards the large set of aircraft steps (giraffe) placed next to the cockpit and down to the ground and on to the seat stand to be wheeled off to the seat bay.

The armourers also loaded other things to the aircraft and I particularly remember the 2.25″ IR Discharger. This was a large electro-mechanical monstrosity which was loaded into a bay in the wing of the aircraft and dispensed hundreds of Infra Red Decoy cartridges and ‘window’ or chaff. It was a nightmare to load and a difficult beast to work on in the servicing bay as well. I remember it was winched up into the wing by 2 mini hoists and then some poor soul had to climb up a ladder and reach in beside it and try and get a couple of pins in to hold the discharger on to the securing points. Invariably the hoist had to be raised and lowered a couple of times to get the discharger seated properly with severe danger to the fingers of the guy trying to fit the pins.

I do remember that the discharger was a real pig and tended to work when it felt like it. Although my memory is going a bit and I can’t remember too many details, the machine consisted of 2 metal belts with cartridges loaded in banks of four so that a total of over 2 hundred cartridges were fitted. The belts were motored round by an electric motor which lined the cartridges up with a set of electric firing pins. However to load the cartridges the use of the electric motor was not a good idea and we had to wind it around by hand which was a real pain.

It wasn’t just on the aircraft that some oddities took place. I worked for a while in the ejection seat bay where we had to strip the seat down to its smaller components (Drogue Gun, barometric unit, Time Delay Unit etc.) . These ‘instruments’ are used to time the various aspects of the ejection process and some where made up of a number of cogs and escapement wheels etc. These had to be removed from their case and thoroughly cleaned to ensure the timing was correct. There was a small room in the seat bay where this process took place and we where supposed to open the window before using the cleaning compound. This cleaning and degreasing compound has now been withdrawn from general use as a substance hazardous to health. Anyone who worked in the RAF in those days will recognise Trich (Trichloroethene). This one particular day one of the lads had been sent off to service the instruments for a set of seats and he hadn’t appeared for tea break, an unusual occurrence at the best of times. I went to see why he wasn’t at tea break and found him sat on the floor in the corner, grinning inanely with the vacuum cleaner on blow trying to sober himself up from the fumes of this noxious fluid. After this we always opened the window in the instrument room.

Talking of sobering up, working in the seat bay was also a really good way of clearing a stuffy head of the morning after the night before. On the side of the ejection seat is a small emergency oxygen bottle which had to be replaced and sent to the oxygen bay at each servicing interval. Hence there was always a ready supply of oxygen and it was not an uncommon sight to see an armourer, slightly dishevelled, sat or stood beside the seat with the oxygen mask clamped to his face.

I wasn’t that lucky at Scampton with the detachments and only managed a few around the UK and only one that I really remember well, abroad. It was a quick trip to Malta with 617 Squadron. There were 2 armourers with the squadron and although there was practice bombing to do, that was just a case of inserting cartridges and pushing on a couple of bombs. What we were supposed to be there for was in case there was an ejection seat snag and we could between us fix it. It was another case of at least 2 people required for vital and independent checks. Well needless to say no seat snags came up and I ran the tea bar did some guarding and generally tried to make myself useful. The social side of the detachment was pretty good though and I was introduced to the local beers in the NAAFI which as far as I can remember were either in a green or a red can and I think that was the only difference. We had a good night out near the end of the detachment with a barbeque on a beach (not sure which one). I shall never forget the sight of the Wing Commander from 617 Squadron, stripped to his underwear, running down the beach; arms outstretched humming the Dambusters March as loudly as he could until he disappeared into the water!

Scampton and the Vulcans will always remain a great memory not least because Scampton is where I met my wife, got married and we set up our first home together in the Married Quarters at what was RAF Faldingworth. Happy Days!

The following article was recently published by James Blatch in his email newsletter. James is author of the novel, The Final Flight. His father, John

Aircraft have become an essential part of all aspects of our day to day lives. Whether through business, pleasure or war, they have been vital

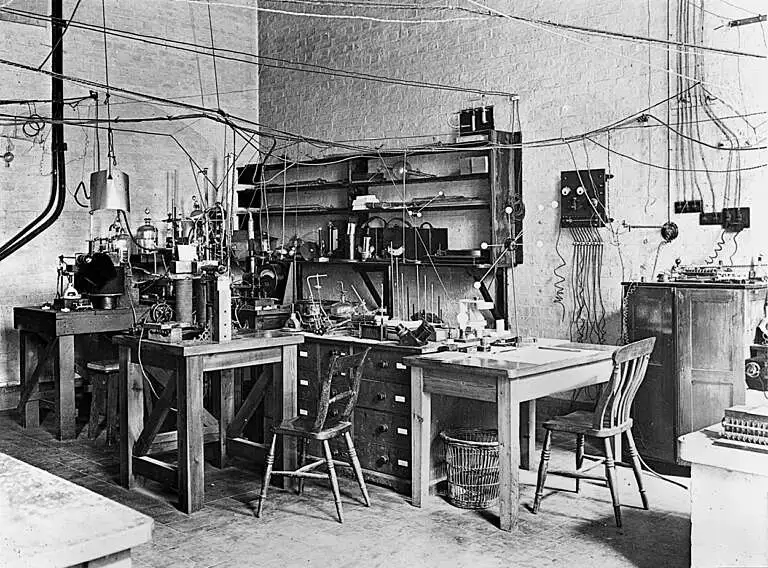

The discovery of the neutron and its properties is central to the extraordinary developments that lead to the first atomic bomb in 1945, and the

Recollections from Headquarters 1 Group RAF Bawtry Hall, RAF Finningley and the Bomber Box. Although I worked for the General Post Office (GPO) or BT