The Importance of a Bulb

Ian Hamilton I was posted to 44 Squadron (Rhodesia Squadron) from RAF Waddington in early 1964 as a 20 year old Air Wireless Fitter. I

Mr. Alan Ainsworth, was on the Flight Test and development Team of AV Roe – read on for an interesting account of the early days, with yet another mention of “that roll”

I first met the Vulcan early in 1956 when I Joined Avro as a Flight Test Observer. The prototypes had been flying since 1952 and had proved that the Vulcan could fly. My work was to be involved with developing the various systems fitted to the aircraft.

Flight Test and Development was located in the flight sheds on the south side of Woodford Airfield and was under the guidance of Cyril Braithewaite, whilst my immediate supervisor was Stan Nicol, the Chief Flight Test Observer. Time has dimmed my memory for names but I recall Frank Burke, Jack Fish and Ted Harley as some of those also involved in Vulcan development testing.

I was soon to learn that for every hour spent in flight another five were to be spent at a desk analysing the results of the tests. Flight Test included a section who had the unenviable task of reading every frame of film we took in flight and writing down in tabular form details of the tests that we conducted . These charming ladies had the patience of Job and an eye for accuracy.

The Vulcans used in development testing were all equipped with an extra -large instrument panel located in the bomb aimers position. The panel was well lit with strip lighting and had two movie cameras focussed upon it. These cameras were remotely controlled from one of the navigators positions in the rear cabin and could be run at one frame every two and one half seconds or, if a test sequence was in progress, at a speed of four frames per second. We also used trace recorders which kept a record of the tests on rolls of paper . A pen traced the progress of the tests as the roll of paper passed beneath it.

During long test sessions the cameras would run out of film and needed a magazine change. This task was simple enough when conducted on the ground but in flight it could be very difficult. The camera would suddenly double in weight, as the pilots pulled “g” forces , and take off across the bench with a mind of its own . Feeding film through the camera spools was a matter of luck and determination. One particular flight however, needed nothing more sophisticated than a clip board and a hand held temperature bulb to complete it.

The weapons systems carried in the Vulcan had to be kept at a constant temperature . Hot air, bled from the engines, was used to heat the bomb bay. The efficiency of this system needed to be checked. I cannot remember if Avro were short of money at the time , or if time itself was short, but the decision was made to mark points of the bomb bay with chalk and have someone ride in the bomb bay to keep a record of the temperatures .

I knew that I was a junior in our office and I had long suspected that I was expendable so it did not come as a surprise to learn that I had been given the job. Avro thoughtfully deactivated the bomb doors and fitted a cushion and safety harness to the forward bulkhead. They also gave me a portable oxygen set and intercom connections to the pilot. I entered the bomb bay through the ventilation grill at the rear of the left hand bomb door, my parachute was then handed in to me. I put it on. It was only later, back at my desk, that the obvious thought occurred to me – getting out through the same hole with a parachute on could have been rather difficult! Vulcans VX 770 and VX 777 had been the prototypes. I flew in 770 but I can’

recall seeing much of 777 because it was in the hangar for long periods having the phase two wings installed. XA 891, XA 893, XA 894 and XA 889 were the aircraft designated for development testing. If my memory serves me correctly XA 890, XA 892, XA 895 and XA 896 were used at Boscombe Down and also at Bristol for engine development. XA 897 was the first Vulcan to be delivered to the RAF at Waddington.

XA 894 was used for the Smiths automatic pilot trials. I flew on two of these flights. By the time that I made this flight the auto-pilo t had been proved under normal conditions of flight – it was now to be tested under adverse conditions. A Smiths engineer was carried on board to operate a device ‘to inject a disturbance’ into the system. The auto-pilot gyros would then topple and the Vulcan took off on a massive roller coaster ride, until the gyros erected once more and stable flight was resumed.

Throughout all these wild rides I operated the cameras and the recorders, all the time retasting my lunch. Matters came to a head after the tests had been completed and we were returning to Woodford. A radio message was received asking us to put in an appearance at Blackpool Air Pageant. We complied with a display which culminated with a fast pass over the field followed by the now famous Vulcan pull up. I made a grab for a brown paper bag. Later I was to learn that my infant son had been at the display and had been told that it was “Daddies aeroplane”. Fortunately he was not aware that his daddy was, at that moment, grabbing yet another brown paper bag. The Vulcan had a wheel brake system made by Dunlop. It incorporated an anti skid device that released the brakes if the wheels locked and skidded on a wet or icy surface. We tested this system at RAF Waddington on a runway that had been specially wetted for the occasion. Unfortunately the Fire Section had not been told to stop the wetting so that the dry part of the runway was at ninety degrees to the runway centerline. As a result the wheels on the port landing gear ran off the wet portion first and tyres scrubbed and burst, leaving us short of rubber on that side. We had five wheels left serviceable out of the eight we started with. I climbed down to inspect the damage and confer with the Dunlop engineer who was present. I reported back to our pilot who informed me that he had a dinner appointment in Manchester that evening and he did not intend to miss it. We taxied out and took off, watched by a horrified Dunlop engineer and an amused bunch of RAF ground crew.

Preceding this braking test we had been conducting tests on the crew entrance door. This was just after the tragic loss of XA 897 at London Airport. Bomber Command crews were voicing concern about the ability of the crew in the rear cabin of the Vulcan to escape, using the door as a slide. We had flown around opening the door at various speeds and altitudes until the air bottle, used to operate the door, was empty. The take off from Waddington started with the door open , since we couldn’t close it. The door closed as forward speed increased, but it didn’t lock. During the quick flight back to Woodford I decided to save some time. I left my seat to remove the magazine from the camera. I forgot all about the door and received the shock of my life when it opened under my weight. I jumped back very quickly – a very scared lad.

More tests on the door followed, this time with the cockpit canopy removed, giving the Vulcan the appearance of a Tiger Moth. These tests were thought necessary in case the canopy was jettisoned by the crew and a negative pressure was created in the cabin, which would hold the door closed. The tests proved conclusively that this would not happen, for the door worked perfectly. What impressed me most was, that with the cockpit canopy removed there was a complete lack of air movement in the rear cabin, not even enough to ruffle a sheet of paper on my desk. Such was the perfection of the aerodynamic shape of the Vulcan nose.

The Vulcan had been designed with a DC electrical system but technology had overtaken it. Modern avionics demanded stable electrical supplies and that meant a completely new type of electrical system.

XA 893 was used to develop the new system. At first it was pretty complicated for the aircraft operated on the old system, with dummy loads fitted in the bomb bay. The inboard engines were equipped with constant speed hydraulic drives which turned the AC generators at a constant 400 cycles per second, despite a variable input speed from the engine. Like all new systems it had teething troubles. At high altitude the oil in the drives frothed and lubrication failed. The drives would shear with a very noticeable “Thump” on the airframe . The dummy loads in the bomb bay consisted of chokes, coils and resistors which could be switched from the cabin to simulate various loads on the AC generators. The loads were cooled in flight by ram air whilst on the ground an electric fan was used. The fan was an after thought and the obvious was over looked. When the aircraft was in flight the fan was motored over by the ram air flow, and turned into a generator. The feed back of electrical current caused a fire. We landed with smoke billowing out of the Vulcan, giving the impression that we were well and truly ablaze.

Another component fitted to the Vulcan at this time was the Rover auxiliary power unit. This unit was based on a design meant for a car, also built by Rover. The APU was fitted behind the left hand main landing gear, in an area originally meant to be occupied by a chaff dispenser. We painted the skin around the APU exhaust with temperature sensitive paints to keep a check on the temperatures, and the effect they were having on the skin. The APU was not a success, at least not at first. It was reluctant to start at altitude and experiments were conducted to introduce neat oxygen into the intake to coax it into starting and finally the whole unit was placed in a box and pressurised in an attempt to make it useful in flight.

The change over to AC power made it necessary to have a standby power source in case of a multiple engine flame out, the APU was to be that source. In addition to that power source we made tests on the engines to try to keep them windmilling at sufficient speed to keep the alternators on line. To do this we stopped an engine at high altitude and put the aircraft into a rapid descent, in an attempt to keep the engine motoring over with the ram air entering the intake. The test was a failure but later, when we evaluated our film records, we noted that we had achieved Mach 1.02 during the dive. Imagine our disappointment however, when we corrected the indicated mach value and discovered that we had actually been diving at Mach 0.97 in true values.

One wet and gloomy November afternoon in 1956 Tony Blackman and I took off from Woodford on what was to be a very routine flight. We carried two radio experts in the rear cabin. They were going to do antenna loop swings on the Post Office facility at Brocton. On this occasion I flew in the co-pilots position so that I could operate the fuel and air conditioning systems. The aircraft was the first production model XA 889. This aircraft was the odd man out on the production line, many of the modifications had not been carried out. Vulcan XA 889 did not have hydraulic pressure gauges. In their place it had magnetic ‘doll’s eye’ indicators, which flicked over to indicate black when all was well in the system, but reverted to show white when the system failed. The loop swings were well advanced, and we were climbing to 40,000 feet for another series of runs, when one of the radiomen complained of feeling unwell, adding that his companion had already collapsed! We initiated an emergency descent to get lower so that we could depressurise and get air into the cabin. It was when we were checking the instruments, for signs of the problem, that we discovered we had lost the hydraulic system. The ‘doll’s eyes’ were showing white. Later we discovered that a hydraulic pipe had failed and allowed fluid to enter the cabin as a fine mist, through the air conditioning system. Tony Blackman and I had been wearing oxygen masks during the flight and these had prevented us from being affected by the fumes. We arrived and now it remained to get XA 889 down safely once more. Tony Blackman elected to make a low pass over the control tower so that they could examine the belly of the aircraft before we lowered the landing gear on the emergency air bottle. The reply he received was outstanding in its northern wit. ‘Can you come back after its stopped raining. We can’t see much from down here” said the voice.

It was by now late afternoon and the gloom was increasing by the minute. Tony Blackman announced that he was diverting to Boscombe Down, and off we went southwards. We landed soon after at Boscombe Down after lowering the landing gear on the emergency system and using the tail braking parachute to assist us in stopping the aircraft. Avro sent the company hack Anson to pick us up and we eventually arrived back at Woodford at about 6.30p.m. Vulcan XA 889 was repaired and returned to Woodford a few days later. A colleague of mine, John Ritchie by name, harboured a secret desire to be the first man in history to leave a Vulcan by parachute. He was admirably qualified to do so because he was a fully paid up member of the Territorial Army Parachute Brigade but to the best of my knowledge he never achieved his ambition. He was, however, a very useful man to have in the crew. The parachutes we wore were of the back-type. The canopy was held in the pack by three pins which could be activated by the release handle when the occasion arose. These pins were very sensitive to movement by the wearer and with the amount of moving around we had to do, it was not unusual to find that the contents of the parachute pack had dumped themselves on the floor of the aircraft. This is where John Ritchie came in. He would eagerly exchange parachutes, then set about repacking the contents of the misbehaving item. I made a flight one day with Jimmy Harrison as the pilot. We were measuring the rates of roll on the Vulcan after modifications had been made to the wing structure. The tests involved trimming the aircraft to fly ‘hands off’ and then using a spring balance to pull the control column over and instigate a roll on the aircraft. This way we could obtain data on the forces required to move the control column. The tests started with relatively small displacements which were gradually increased until the forces pulled on the spring balance produced a roll where the wings were vertical. Jimmy Harrison remarked that the Vulcan was handling beautifully and felt as if it was eager to make a complete roll. On the next pull of the spring balance Jimmy allowed it to do just that. We rolled 360 degrees and, just to prove it was easy, we did it again. This was some years after Roly Falk rolled the Vulcan at Farnborough but it was still a fine experience, especially if you were there. In the rear of the Vulcan the effects of a 360 degree roll were very tame for we had no horizon to compare our attitude with. Our only natural light came from two ‘eyebrow’ windows in the fuselage side and a trio of periscopes used mostly for checking on the operation of the wing air brakes, which appeared as if by magic on tracks from the surface of the wings, to dump lift as required. The trials on the auto-pilot fitted to XA 894 continued. By now they had progressed to a very advanced stage and were being conducted with the automatic pilot coupled to the Instrument Landing System. This meant that the Vulcan could make a blind approach to a landing under appalling weather conditions. This was years before similar systems were fitted to civil airliners. The tests were conducted at RAe Bedford. At about 20 miles from touch-down the Vulcan captured the localiser beam and tracked towards the runway, with the automatic pilot in control. Closer in the system captured the glideslope and the aircraft started its final descent to the runway. During my time we never went lower than 200 feet above the runway. The pilot would disengage the auto-pilot and initiate a go around, preparing for another run. As the aircraft flew away from Bedford the Smiths engineer would be replacing small gears in the auto-pilot system to change the rate of response made by the auto-matic pilot to the radio signals. We would then commence another test run. Much of these approaches were made with the engines running at idle speed. After one such approach, as the pilot opened up the engines to make a go around, number one engine exploded throwing debris forward, so that it entered number two engine. This engine also gave up the ghost and we completed the flight back to Woodford on just the starboard engines, no great problem I was told later. This failure came at a very critical time during the Olympus engine development, for it was hoped to have it cleared for service in the RAF . Much midnight oil was burnt and more tests were flown, this time with the compressors of one engine fitted with equipment calibrated to show the resonance levels felt by the engine at various power settings. The tests indicated that the highest resonance was experienced at flight idle. Bristol countered this by adjusting the idle speed by 50rpm to 4850 and the problem was cured. Boffins began to breathe again. I left the Vulcan in October 1957 to start a new life in Canada. Much has happened to me since those days, but that is a different story. I consider it to have been one of the highlights of my career to have been involved with Vulcan and to have met and worked alongside those who designed, built and flew her. She was, is and ever will be a magnificent aircraft. Much of her technology exists today in that other marvellous lady, Concorde. Long may they both continue to grace our skies.

Ian Hamilton I was posted to 44 Squadron (Rhodesia Squadron) from RAF Waddington in early 1964 as a 20 year old Air Wireless Fitter. I

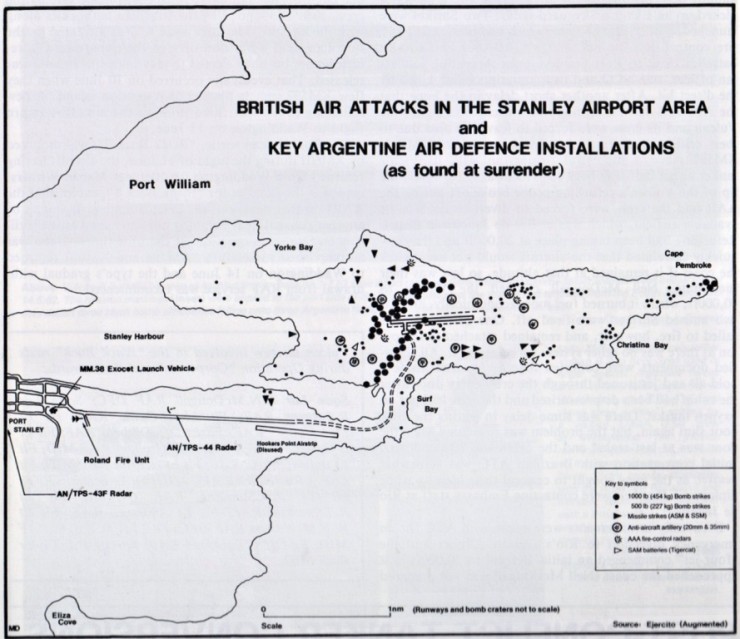

2022 is the 40th Anniversary of The Falklands Conflict and the audacious Black Buck missions carried out by the Royal Air Force. On 2 April

Vulcan to the Sky volunteer Geoff Higley, who lives in Grantham, was in the airforce for 20 years as a navigator. Here in our Q and A

The success of the Canberra as a research aircraft over the years is a testament to “Teddy” Petter’s original design. It had all the important